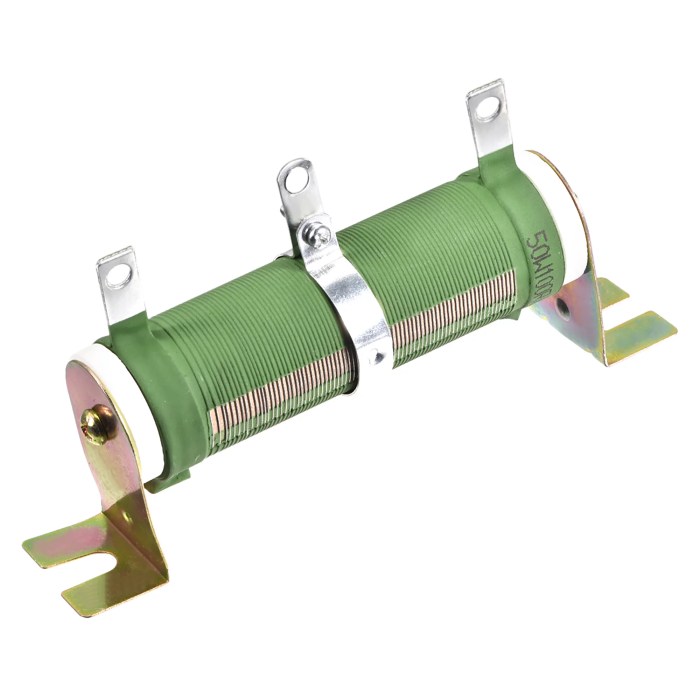

How should tubular wire-wound resistors be mounted and why? This question is of paramount importance for ensuring the optimal performance and longevity of these essential electronic components. In this comprehensive guide, we will delve into the various mounting options available, exploring their advantages and disadvantages, and highlighting the critical considerations for heat dissipation, electrical isolation, mechanical stability, and environmental protection.

By understanding these factors, engineers can make informed decisions about the most appropriate mounting method for their specific applications.

Mounting Options: How Should Tubular Wire-wound Resistors Be Mounted And Why

Tubular wire-wound resistors can be mounted in various ways, each with its advantages and disadvantages:

- Axial mounting:Resistors are mounted parallel to the circuit board, with leads extending from both ends. This method provides good heat dissipation but requires more space on the board.

- Radial mounting:Resistors are mounted perpendicular to the circuit board, with leads extending from one end. This method saves space but can result in reduced heat dissipation.

- Surface mount:Resistors are mounted directly onto the circuit board, with no leads. This method is space-efficient and provides excellent heat dissipation.

Heat Dissipation Considerations

Tubular wire-wound resistors generate heat during operation. Proper mounting is crucial for ensuring effective heat dissipation:

- Axial mounting allows for better heat dissipation through the leads and the surrounding air.

- Radial mounting can limit heat dissipation, especially if the resistors are mounted close together.

- Surface mount resistors typically have lower power ratings than axial or radial resistors, so heat dissipation is a critical factor.

- Washers or insulating materials can be used to provide electrical isolation.

- Improper electrical isolation can lead to arcing, overheating, and potential circuit damage.

- Axial mounting provides better mechanical stability due to the support provided by the leads.

- Radial mounting can be less stable, especially if the resistors are not properly secured.

- Surface mount resistors require careful mounting to ensure they are securely attached to the circuit board.

- Moisture and dust can cause corrosion and affect the resistor’s resistance value.

- Extreme temperatures can lead to thermal stress and damage the resistor.

- Proper mounting can protect the resistors from these environmental factors by providing a barrier and ensuring adequate ventilation.

Electrical Isolation Requirements

Electrical isolation between the resistor and its mounting surface is essential to prevent short circuits and ensure proper operation:

Mechanical Stability

Ensuring mechanical stability is crucial for tubular wire-wound resistors, especially in applications subject to vibration or shock:

Environmental Considerations

Environmental factors can affect the performance of tubular wire-wound resistors:

FAQ

What is the most common mounting method for tubular wire-wound resistors?

Axial mounting is the most common method, where the resistor is mounted along its axis, with its leads extending from opposite ends.

Why is heat dissipation important for tubular wire-wound resistors?

Heat dissipation is crucial because excessive heat can degrade the resistor’s performance and reduce its lifespan. Proper mounting ensures adequate heat transfer away from the resistor.

What is the purpose of electrical isolation in resistor mounting?

Electrical isolation prevents electrical current from flowing between the resistor and its mounting surface, which can cause short circuits and damage the circuit.

How can mechanical stability be ensured for tubular wire-wound resistors?

Mechanical stability is achieved by securely mounting the resistor to prevent vibration and shock from damaging its delicate internal structure.

What environmental factors should be considered when mounting tubular wire-wound resistors?

Environmental factors such as moisture, dust, and extreme temperatures can affect the resistor’s performance. Proper mounting protects the resistor from these elements.