A brake system metering valve – At the heart of a vehicle’s braking system lies a crucial component: the brake system metering valve. This unsung hero plays a pivotal role in ensuring safe and effective braking by regulating brake fluid pressure distribution. Delve into the world of brake system metering valves, where engineering precision meets driving safety.

Brake system metering valves come in various types, each with its advantages and disadvantages. Proportional valves adjust pressure based on load, while non-proportional valves maintain a fixed pressure ratio. Understanding their working mechanisms and proper maintenance is essential for optimal braking performance.

Brake System Metering Valve

The brake system metering valve is an essential component in a vehicle’s braking system. Its primary function is to regulate the hydraulic pressure distribution to the rear wheels during braking.

The metering valve ensures that the rear wheels receive the appropriate amount of braking force, preventing them from locking up prematurely. This helps maintain vehicle stability and control during braking, especially on slippery or uneven surfaces.

Types of Brake System Metering Valves

Brake system metering valves regulate the hydraulic pressure distributed to the front and rear brakes, ensuring balanced braking performance. Different types of metering valves are employed in vehicles, each with its advantages and disadvantages.

Proportional Valves

Proportional valves adjust the pressure distribution based on the load distribution on the vehicle. They maintain a constant pressure ratio between the front and rear brakes, regardless of the vehicle’s weight or load.

- Advantages:Consistent braking performance under varying load conditions, improved stability during braking.

- Disadvantages:More complex design, potential for pressure fluctuations during sudden load changes.

Non-Proportional Valves

Non-proportional valves provide a fixed pressure distribution between the front and rear brakes. They are simpler in design and less expensive than proportional valves.

- Advantages:Simple design, cost-effective.

- Disadvantages:Limited ability to adjust for varying load conditions, potential for rear wheel lockup during hard braking.

Other Types

In addition to proportional and non-proportional valves, other types of metering valves include:

- Combination Valves:Combine the functionality of proportional and non-proportional valves, providing a balance between performance and cost.

- Load-Sensing Valves:Automatically adjust the pressure distribution based on the vehicle’s load, ensuring optimal braking under varying conditions.

Working Mechanism of a Brake System Metering Valve

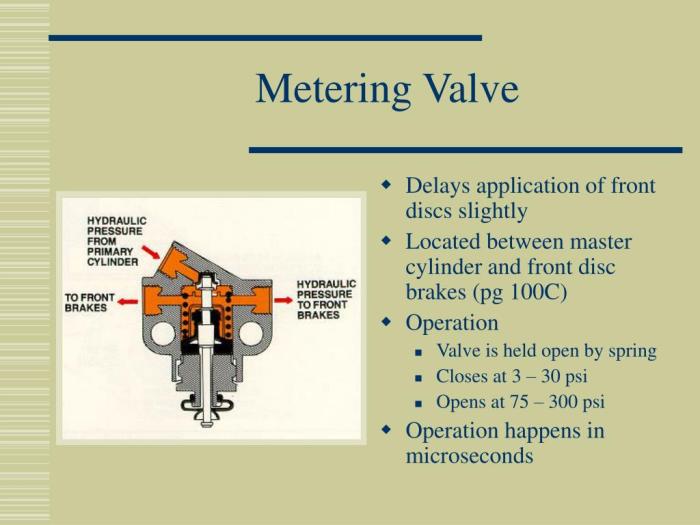

A brake system metering valve plays a crucial role in regulating brake fluid pressure based on load and driving conditions. Its working principle involves a combination of internal components that interact to ensure optimal braking performance.

Internal Components and their Functions, A brake system metering valve

- Springs:Calibrated springs provide a reference force that opposes the pressure exerted by brake fluid.

- Pistons:Pistons move within the valve body, regulating the flow of brake fluid based on pressure differences.

- Diaphragms:Flexible diaphragms separate different pressure chambers within the valve, responding to changes in pressure and adjusting fluid flow accordingly.

As brake fluid pressure increases, the force exerted on the pistons overcomes the spring force, allowing fluid to flow through the valve. The diaphragm then responds to the pressure differential, adjusting the position of the pistons to regulate the flow rate.

Location and Installation of Brake System Metering Valves

Brake system metering valves are typically located in the brake line between the master cylinder and the rear axle. They are usually mounted on the frame or firewall of the vehicle. To locate the metering valve, follow the brake line from the master cylinder.

The metering valve will be the first component in the line after the master cylinder.To access the metering valve for inspection or replacement, you will need to remove the brake line from the valve. Be sure to use a flare nut wrench to avoid damaging the line.

Once the brake line is removed, you can unscrew the metering valve from the frame or firewall.When installing a new metering valve, be sure to tighten it to the specified torque. You should also use a new crush washer on the brake line fitting.

Maintenance and Troubleshooting of Brake System Metering Valves

Maintaining brake system metering valves is crucial for ensuring optimal brake performance and safety. Regular inspections and servicing can help identify potential issues early on, preventing costly repairs or accidents.

To master the nuances of a brake system metering valve, you might want to check out vita basic exam answers 2023 . This resource offers a comprehensive guide to understanding the intricate workings of this essential component. By delving into its pages, you’ll gain a deeper appreciation for the role it plays in ensuring optimal braking performance.

Common signs of a faulty metering valve include:

- Uneven brake pressure distribution, resulting in one wheel locking up before the others.

- Spongy or soft brake pedal feel.

- Excessive brake fluid loss.

- Vehicle pulling to one side during braking.

Troubleshooting Steps:

If you suspect a problem with your brake system metering valve, follow these steps to troubleshoot and resolve the issue:

- Inspect the metering valve for any visible leaks or damage.

- Check the brake fluid level and top it up if necessary.

- Test the metering valve by applying pressure to the brake pedal and observing the fluid flow through the valve.

- If the metering valve is not functioning properly, it may need to be replaced.

Advancements in Brake System Metering Valve Technology

The brake system metering valve has undergone significant advancements in recent years, driven by the need for improved braking performance, safety, and efficiency. These advancements have resulted in the development of innovative technologies that enhance the overall braking system.

Electronic Brakeforce Distribution (EBD)

Electronic Brakeforce Distribution (EBD) is a system that uses sensors to detect the load on each wheel and adjusts the brake pressure accordingly. This ensures that each wheel receives the optimal amount of braking force, preventing skidding and maximizing stopping power.

Anti-lock Braking Systems (ABS)

Anti-lock Braking Systems (ABS) prevent the wheels from locking during braking, allowing the driver to maintain control of the vehicle. ABS uses sensors to detect when a wheel is about to lock and modulates the brake pressure to prevent it.

Hydraulic Brake Assist (HBA)

Hydraulic Brake Assist (HBA) is a system that detects emergency braking situations and applies additional brake pressure to help the driver stop the vehicle more quickly. HBA uses sensors to measure the rate of deceleration and applies additional pressure when it detects a sudden drop.

General Inquiries: A Brake System Metering Valve

What is the primary function of a brake system metering valve?

To regulate brake fluid pressure distribution, ensuring optimal braking force and preventing rear wheel lockup.

What are the common types of brake system metering valves?

Proportional valves (adjust pressure based on load) and non-proportional valves (maintain a fixed pressure ratio).

How do I know if my brake system metering valve is faulty?

Signs include uneven braking, excessive brake pedal travel, or rear wheel lockup during braking.